Precision turning tool holder: Enhancing precision and efficiency in turning operations

The Turning Tool Holder is a versatile and essential tool used in a variety of machining applications across different industries.

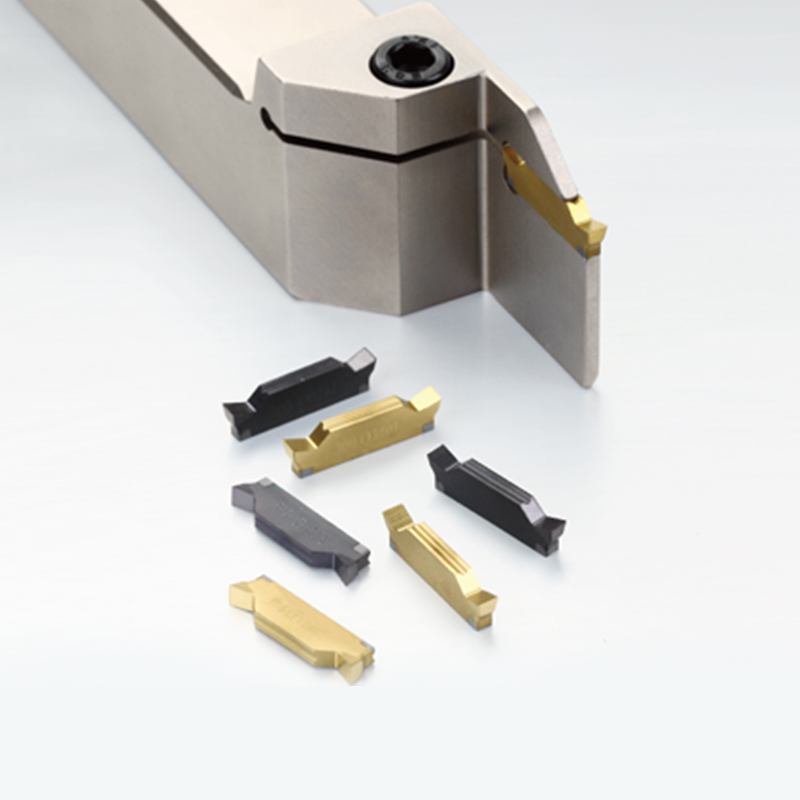

The Turning Tool Holder is extensively utilized in precision turning operations, such as external and internal turning, facing, grooving, threading, and chamfering. It enables precise metal removal and shaping, allowing for the production of intricate components with tight tolerances.

In computer numerical control (CNC) machining processes, the Turning Tool Holder is an integral part of the tooling setup. It is compatible with CNC lathes and turning centers, enabling automated and precise machining of various materials, including metals, plastics, and composites.

The Turning Tool Holder plays a critical role in the automotive industry, where it is used for turning operations on engine components, transmission parts, braking systems, and other critical automotive parts. It ensures the accurate shaping and finishing of these components, contributing to their performance, reliability, and quality.

Aerospace applications demand high precision and quality. The Turning Tool Holder is extensively used in machining aerospace-grade materials, such as titanium alloys, aluminum alloys, and high-temperature alloys. It enables the production of complex aerospace components, including turbine blades, aircraft engine parts, and structural elements.

The Turning Tool Holder finds widespread use in general engineering workshops, job shops, and manufacturing facilities. It is employed for various turning applications, ranging from small-scale production to large-scale manufacturing, across different industries like metalworking, fabrication, and assembly.

The Turning Tool Holder is indispensable in maintenance and repair operations across industries. It facilitates the repair and refurbishment of worn-out or damaged parts, allowing for the restoration of machinery and equipment to optimal working condition.

In woodworking and furniture manufacturing, the Turning Tool Holder is utilized for lathe turning operations on wood, creating intricate designs, profiles, and decorative elements. It enables woodworkers to achieve precision and finesse in their projects.

The Turning Tool Holder’s versatility, precision, and compatibility with various turning processes make it a crucial tool in industries such as automotive, aerospace, general engineering, and woodworking, contributing to efficient and accurate machining operations.

The Cowee Turning Tool Holder is designed with a robust and rigid construction, ensuring excellent tool stability during machining. This feature minimizes vibrations, reduces chatter, and enhances cutting performance, resulting in superior surface finish and dimensional accuracy.

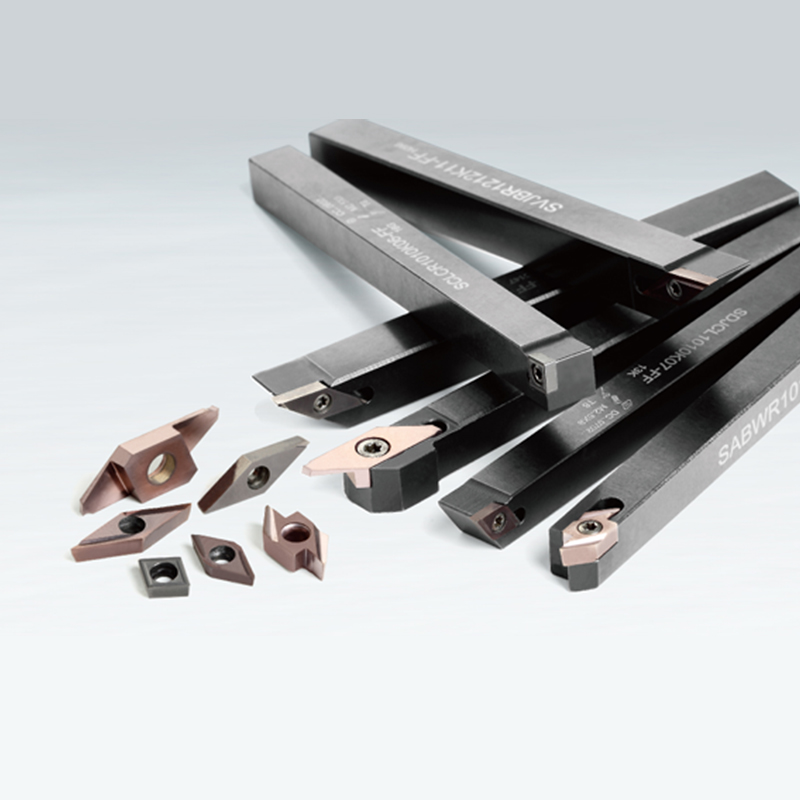

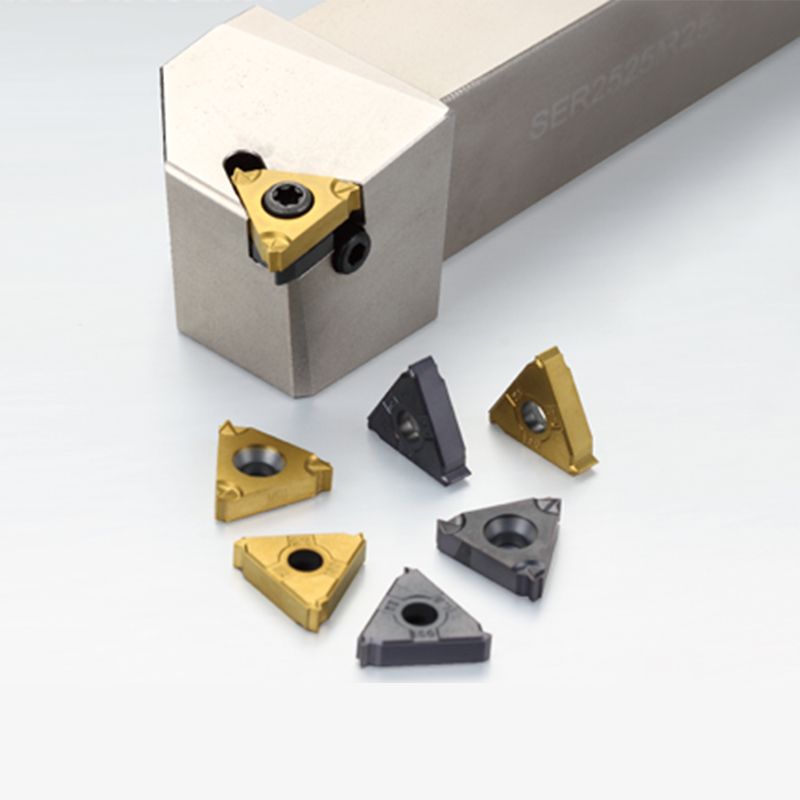

The Turning Tool Holder by Cowee is compatible with a wide range of inserts, providing versatility in tooling options. It accommodates various insert geometries, grades, and chip breakers, allowing for flexibility in adapting to different materials, machining conditions, and cutting requirements.

With precise manufacturing and meticulous craftsmanship, the Cowee Turning Tool Holder enables high-precision machining operations. Its accurate tool positioning and exceptional clamping mechanism ensure consistent and repeatable cutting performance, delivering tight tolerances and excellent part quality.

The Turning Tool Holder incorporates efficient chip evacuation features, including optimized chip breaker designs and chip control grooves. This facilitates the smooth and effective removal of chips from the cutting zone, preventing chip clogging and promoting uninterrupted machining, leading to improved productivity and tool life.

Cowee's Turning Tool Holder is engineered with innovative coolant delivery systems that efficiently direct coolant to the cutting zone. This helps dissipate heat, lubricate the cutting interface, and flush away chips, resulting in extended tool life, improved surface finish, and enhanced process reliability.

The Cowee Turning Tool Holder features a user-friendly insert clamping mechanism, ensuring quick and secure insert changes. This reduces setup time and enhances operational efficiency, allowing for seamless transitions between different cutting operations and insert geometries.

The Cowee Turning Tool Holder combines superior tool stability, versatility in insert compatibility, high precision machining capabilities, efficient chip evacuation, enhanced coolant delivery, easy insert clamping, and durable construction. With these outstanding features, it empowers machinists to achieve optimal performance, productivity, and quality in their turning processes.

Contact Cowee to Start Your Business

Driven by expertise, committed to excellence, your trusted partner