Оглавление

ПереключатьCarbide Tipped Chop Saw Blade

When it comes to precision cutting, the choice of the right tool can make all the difference. A отрезное полотно с твердосплавным наконечником stands out as a popular option among professionals and DIY enthusiasts alike. These specialized blades are designed to cut through various materials with efficiency and accuracy. But with so many options available, how do you choose the right carbide tipped chop saw blade for your specific cutting needs?

Understanding the Basics of Carbide Tipped Blades

Before diving into the specifics, let’s understand what a carbide tipped chop saw blade is. Unlike standard steel blades, carbide tipped blades have tips made from a mixture of tungsten and carbon—known for their hardness and durability. These tips can maintain sharpness longer than their non-tipped counterparts, which means fewer replacements and interruptions in work.

Imagine a builder who frequently cuts through steel pieces for a structure. If he uses a standard steel blade, he might find himself stopping to replace it often, wasting valuable time and effort. However, with a carbide tipped chop saw blade, he can work more efficiently, producing clean and precise cuts without frequent blade changes.

Benefits of Carbide Tipped Chop Saw Blades

1. Повышенная долговечность

One of the most significant benefits of carbide tipped chop saw blades is their durability. When cutting through tough materials such as stainless steel or hard metals, a carbide tipped blade stands up to the challenge far better than a traditional blade. This durability translates into cost savings over time, as users do not need to replace blades as frequently.

2. Clean Cuts

Another tangible advantage is the quality of the cuts. The sharpness of carbide tips allows for smoother, cleaner cuts, minimizing burrs and splinters. For instance, a metal fabricator needing precise cuts for intricate designs would benefit greatly from using a carbide tipped chop saw blade, ensuring that edges are ready for immediate assembly or welding without additional finishing.

3. Универсальные приложения

Carbide tipped chop saw blades are not limited to only metal cutting. They are highly versatile and can be used for various materials, including wood and plastic. For example, a contractor might use a carbide tipped blade to efficiently cut through plywood for cabinetry while also tackling a metal frame—all requiring precise cuts but with different materials. This adaptability can lead to increased productivity and a more streamlined workflow.

Selecting the Right Blade for Your Needs

When it comes to selecting a carbide tipped chop saw blade, several factors should be taken into account:

1. Tooth Count

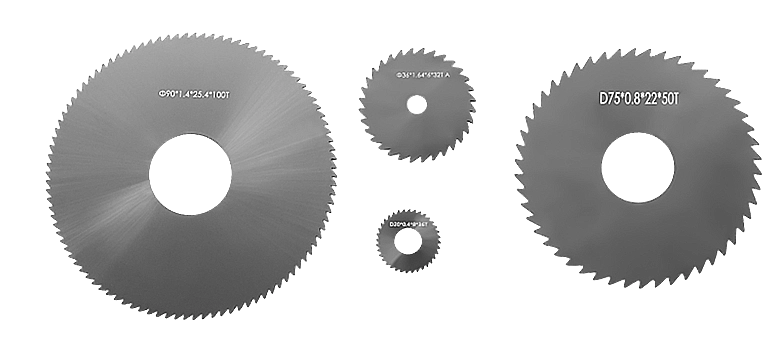

The tooth count on a carbide tipped chop saw blade significantly influences the type of cut you will achieve. A lower tooth count (around 24 teeth) is better for quick, rough cuts, especially in thicker materials. Conversely, a higher tooth count (60 teeth or more) is ideal for smooth, finer cuts.

For example, if you are working on a woodworking project where aesthetics matter, choosing a blade with a higher tooth count will help provide the smooth finish required for visible parts. However, if you are cutting through thicker metal where speed is a priority, a blade with fewer teeth will quickly get the job done.

2. Blade Thickness

Blade thickness also plays an essential role in cutting. Thicker blades may offer increased stability and reduced vibration, leading to more accurate cuts. Conversely, thinner blades may cut faster but can be more prone to flexing and bending, particularly in tougher materials.

Consider a scenario where a fabricator uses a thicker carbide tipped chop saw blade for cutting through heavy steel. The added stability would allow for a more controlled cut, reducing the chances of damaging both the material and the blade.

3. Coatings and Finishes

Some carbide tipped blades come with special coatings designed to reduce friction and heat buildup during cutting. These coatings can enhance the performance of the blade and increase its lifespan. A blade with a special finish might be particularly advantageous for someone consistently working with metals, as it would withstand heat better than a standard uncoated blade.

Техническое обслуживание и уход для долговечной работы

Even the best carbide tipped chop saw blades require proper maintenance for optimal performance. Keeping the blade clean and free from debris is critical. When not in use, storing the blades properly away from moisture will also prevent rust and damage that could lead to reduced cutting efficiency.

Regularly checking the sharpness of the blade will help determine when it is time for a replacement. A simple test is to attempt cutting through scrap material; if the cut is less than satisfactory, it may be time to consider a new carbide tipped chop saw blade.

Заключение

In conclusion, choosing the right carbide tipped chop saw blade involves understanding your specific cutting needs, the materials you work with, and the applications you require. The benefits of durability, clean cuts, and versatility make these blades an excellent choice for anyone serious about their cutting tasks. Whether you are a professional contractor or a DIY enthusiast, investing in a good quality carbide tipped chop saw blade can enhance your efficiency and the quality of your work.

As you consider your next project, think about the blade you will use. With the right carbide tipped chop saw blade in hand, you are not just cutting through materials; you are elevating your craft and ensuring that precision and quality define your work. Embrace the power of the carbide tipped chop saw blade to unlock new possibilities in your cutting endeavors.