Spis treści

Dźwignia kolankowaTungsten Carbide Multi Tool Blades

Tungsten carbide multi tool blades are rapidly gaining recognition for their superior performance in various applications. Whether you are a professional in construction, woodworking, or metalworking, understanding the benefits of these blades can enhance your workflow and the quality of your output. In this article, we will explore the specific advantages of tungsten carbide multi tool blades, their application areas, and how they can significantly improve efficiency.

What Makes Tungsten Carbide Multi Tool Blades Unique?

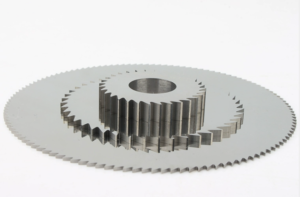

The uniqueness of tungsten carbide multi tool blades lies in their material composition. Tungsten carbide, a compound of tungsten and carbon, is known for its exceptional hardness and wear resistance. This means that blades made from this material can last longer and maintain their sharpness even under tough working conditions. For instance, in a woodworking shop where frequent cuts through dense materials are necessary, a tungsten carbide blade will outperform traditional steel blades by retaining its edge and thus requiring fewer replacements.

Enhanced Cutting Performance

One of the most significant benefits of tungsten carbide multi tool blades is their cutting performance. These blades can slice through materials that would dull standard blades almost immediately. For example, when tasked with cutting through hardwood or composite materials, professionals find that tungsten carbide blades make cleaner cuts with less effort. This not only enhances the look of the final product but also reduces the amount of sanding or finishing work needed afterward.

An illustrative case is that of a contractor who switched to tungsten carbide blades for a remodeling project involving hardwood flooring. The contractor noted that while using standard blades, he frequently had to stop to change them out—delaying the project. However, with tungsten carbide multi tool blades, he could complete intricate cuts in a fraction of the usual time. This resulted in increased productivity and satisfied clients.

Versatility Across Various Applications

Tungsten carbide multi tool blades excel in versatile applications. They can be used not only in woodworking but also in metalworking and construction tasks. For example, these blades are favored in tile cutting. The exceptional hardness of tungsten carbide allows for clean cuts through various types of tiles, including porcelain and ceramics, without chipping or breaking. A tile installer using tungsten carbide blades would find that the speed at which cuts can be made translates to job efficiency, impacting the overall project timeline.

Moreover, the durability of tungsten carbide multi tool blades extends their usability beyond initial tasks. A landscaping professional, for instance, may start with cutting through tough shrubs and brush. With a tungsten carbide blade, the same tool can then be used to handle softer materials such as grass or softer underbrush without jeopardizing the blade’s integrity. This multi-functionality is particularly appealing to contractors who wish to invest in tools that promise longevity and versatility.

Opłacalność w czasie

While tungsten carbide multi tool blades may have a higher upfront cost compared to standard blades, they prove to be more economical in the long run. Their longevity means less frequent replacements, which mitigates the overall expenses associated with tool maintenance, repair, and replacement. Consider the case of a fabrication shop where several employees are assigned to cutting applications daily. By switching to tungsten carbide blades, the shop calculated significant savings through reduced downtime and replenishing costs.

Additionally, buyers need to consider the time saved associated with fewer blade changes and the convenience of longer-lasting performance. This not only allows for a more efficient workflow but can also lead to faster project completions, thus increasing profitability.

Zagadnienia bezpieczeństwa

When using any cutting tool, safety is always a primary concern. Tungsten carbide multi tool blades contribute to improved safety as their higher durability means blades are less likely to break or shatter during use. This is particularly important in high-speed applications where debris can cause severe injuries. An example is in construction sites where angles and pressure can lead to dangerous situations with tools that are not robust enough for the task. Using tungsten carbide can enhance the safety of workers by minimizing the risk of blade failure, as users have confidence that the tool is up to the demands of the job.

In summary, tungsten carbide multi tool blades stand out due to their unique material properties, enhanced cutting performance, versatility, and cost-effectiveness over time. Professionals across various industries recognize the substantial benefits that come with investing in quality blades, as seen in numerous real-case scenarios from carpentry to landscaping. If you are looking to improve your workflow, reduce project times, and ensure safety while working, consider tungsten carbide multi tool blades as a valuable addition to your toolkit.

In today’s competitive landscape, making informed decisions about tools like tungsten carbide multi tool blades can significantly impact your productivity and the quality of your work. Whether you are a DIY enthusiast or a seasoned professional, these blades can enhance your performance and ultimately lead to better outcomes for your projects. Embrace the ingenuity that tungsten carbide multi tool blades bring to the table, and see how they can transform your work.