Cowee – solid carbide saw blades for standard metals, and non-standard products can be customized according to needs

Cowee – solid carbide saw blades for standard metals, and non-standard products can be customized according to needs

Solid Carbide Saw Blades are suitable for processing metal workpieces of various shapes, including but not limited to the following shapes:

Solid Carbide Saw Blades can be used to cut metal bars, such as metal tubes, metal bars, etc.

Solid Carbide Saw Blades are suitable for cutting metal blocks, such as metal plates, metal billets, etc.

Solid Carbide Saw Blades can be used to cut metal pipes, such as steel pipes, aluminium pipes, etc.

Solid Carbide Saw Blades are suitable for cutting various shaped metal workpieces, such as metal profiles, metal parts, etc.

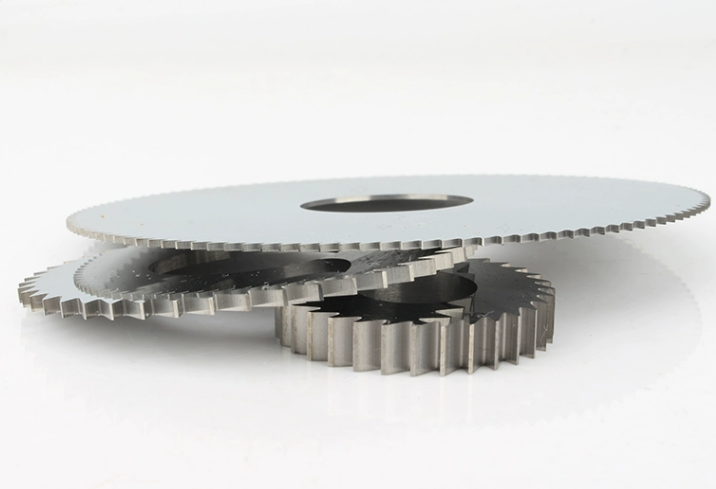

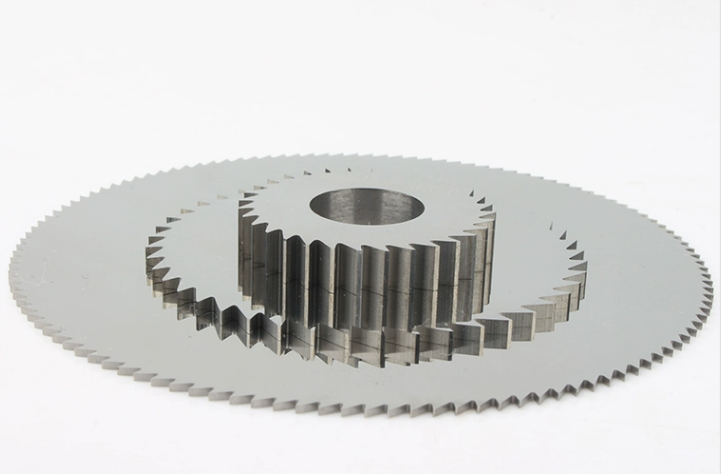

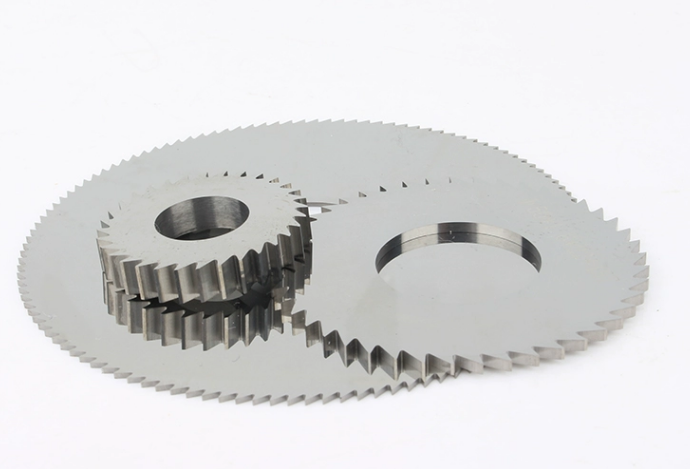

It should be noted that the applicability of solid carbide saw blades mainly depends on the design of their cutting teeth and discs. Different types of cutting teeth and discs are suitable for different types of metal materials and workpiece shapes. When choosing solid carbide saw blades, you need to select the appropriate cutting teeth and discs according to the specific shape, size and material of the workpiece to ensure efficient and precise cutting results.

Solid Carbide Saw Blades have several advantages:

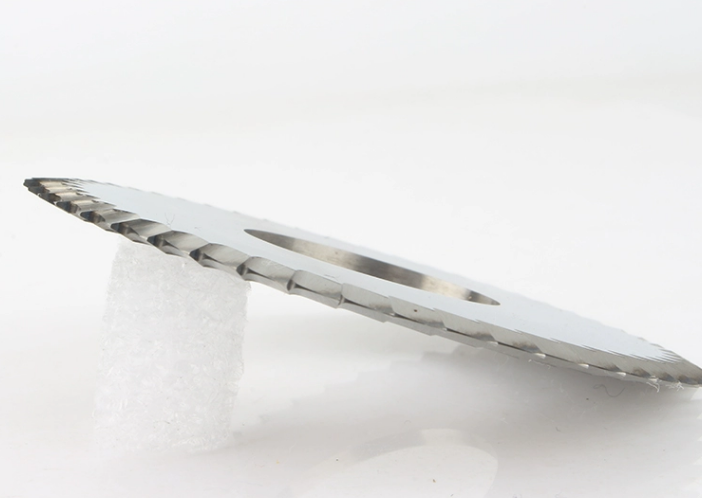

Solid carbide saw blades consist of carbide cutting teeth and steel discs, the carbide has very high hardness and wear resistance, which can maintain a long life in high speed rotation and cutting operations.

Solid carbide saw blades are able to cut at high rotational speeds to finish the workpiece quickly. It provides faster cutting speeds and higher productivity than other cutting tools.

Solid carbide saw blades are suitable for cutting a wide range of materials, including metals, wood, plastics, composites and more. Different types of cutting tooth blades and blade designs can be used for cutting operations on different materials, providing greater adaptability and flexibility.

Solid carbide saw blades cut with evenly distributed teeth, which reduces cutting force and thermal impact and lowers the risk of workpiece deformation. This helps to improve the quality of the cut and extends the life of the tool and workpiece.

Solid carbide saw blades provide precise cuts that result in smooth cutting surfaces and accurate dimensions. This is important for machining workpieces that require high precision.

Solid carbide saw blades have cutting teeth that can be resharpened, prolonging tool life and reducing machining costs.

Overall, tungsten solid carbide saw blades offer the advantages of high hardness, wear resistance, efficient cutting, versatility, reduced cutting forces and thermal effects, providing precise cuts, and resharpenability. It is an important cutting tool that is widely used in various industries for cutting and machining of workpieces.

Contact Cowee to Start Your Business

Driven by expertise, committed to excellence, your trusted partner