Spis treści

Dźwignia kolankowaCarbide Rod with High Hardness

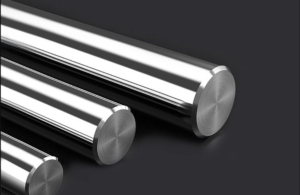

In today’s fast-paced manufacturing world, the tools we use must meet rigorous standards for performance and durability. One of the standout materials in this regard is the carbide rod with high hardness. This exceptional material is recognized for elevating the performance of cutting tools and various industrial applications, making it an essential choice for engineers and manufacturers alike.

Understanding Carbide Rods

Before diving deep into why carbide rods with high hardness are so beneficial, let’s clarify what they are. Carbide rods are tools made primarily of tungsten carbide, a tough material formed by combining tungsten and carbon. When we refer to a “high hardness” version, we signify a product that has been engineered to achieve superior hardness and wear resistance, essential attributes in tool manufacturing.

These rods come in different lengths and diameters, allowing for versatile application across various industries, including aerospace, automotive, and metalworking. Manufacturers across the globe are increasingly looking to carbide rods with high hardness for their operations.

Enhancing Tool Performance

When we talk about the performance of cutting tools, we refer to their efficiency, speed, and precision. Carbide rods with high hardness contribute significantly to these attributes. For instance, when a cutting tool is made from such a rod, it can maintain sharp edges for longer periods compared to tools made from softer materials. This sharpness translates into cleaner cuts, reducing the need for frequent tool changes and minimizing downtime in production.

To illustrate, consider a machining shop that frequently cuts through tough metals, such as stainless steel or hardened alloys. Utilizing cutting tools made from carbide rods with high hardness allows operators to achieve faster feed rates and better surface finish quality. As a result, the machining process becomes not only efficient but also cost-effective, as less time and resources are spent on tool upkeep.

Increased Durability

Durability is another key feature of carbide rods with high hardness. These rods exhibit exceptional resistance to wear and tear, enabling them to withstand heavy loads and abrasive materials. For example, in the woodworking industry, tools crafted from high hardness carbide rods can effortlessly slice through dense hardwood without showing signs of wear, ensuring longer service life.

Moreover, these rods can tolerate extreme temperatures created during high-speed machining processes. Traditional materials might expand or deform under such conditions, leading to inaccuracies and the potential for costly mistakes. In contrast, carbide rods with high hardness maintain their structural integrity, making them a reliable choice for high-performance applications.

Application Areas

The versatility of carbide rods with high hardness extends to various industrial applications. Here are a few areas where these rods truly shine:

1. Metal Cutting: As mentioned earlier, the machining of metals benefits tremendously from high hardness carbide rods. Industries engaged in manufacturing automotive parts or machinery components heavily rely on it.

2. Woodworking: In woodworking, the high hardness guarantees that cutting tools endure extended use, whether shaping intricate designs or cutting thick lumber.

3. Mining and Drilling: The mining industry demands robust materials that can cut through rock and dense earth formations. Carbide rods with high hardness enhance the durability of bits and drills, enabling them to penetrate tough surfaces with ease.

4. Medical Instruments: Precision matters in medical applications. Instruments constructed from high hardness carbide rods ensure accuracy and longevity, which is paramount in surgical environments.

5. Aerospace Manufacturing: The aerospace sector requires materials that can withstand stringent performance criteria. Carbide rods provide the precision and durability needed for fabricating complex components.

6. High-Performance Tools: Many specialized tools, such as end mills, inserts, and drills, benefit from the high hardness of carbide rods, offering users extended tool life and reliability.

Customer Considerations

When looking to purchase carbide rods with high hardness, customers often prioritize several factors.

Quality and Specifications: Buyers typically seek rods with established hardness ratings, ensuring they meet their specific machining requirements.

Supplier Reputation: Trusting a reliable supplier who can guarantee quality control and consistency in production is crucial. Customers want assurance that they are receiving genuine products that will perform as promised.

Cost-Efficiency: While carbide rods, particularly those with high hardness, may come with a higher initial price, customers recognize the long-term cost savings resulting from their extended life and reduced maintenance needs.

Technical Support: Many buyers appreciate suppliers that offer guidance on selecting the right type of carbide rod for their specific applications. Support can also encompass advice on usage and maintenance tips.

Wniosek

In summary, the carbide rod with high hardness is an outstanding choice for those seeking enhanced tool performance and durability. With applications spanning from metalworking and woodworking to aerospace manufacturing, its importance in various industries is unquestionable. The benefits of using these rods—from extended tool life and increased durability to improved operational efficiency—make them an ideal asset in modern manufacturing processes.

As the needs of industries evolve and become more complex, the demand for materials that deliver on performance and durability will continue to grow. Investing in carbide rods with high hardness enables manufacturers to stay ahead in a competitive landscape, ensuring that they can meet the challenges of today and tomorrow. By choosing tools built with this robust material, customers not only enhance their productivity but also set their operations up for sustained success.

Ultimately, embracing high-quality solutions like carbide rods with high hardness is a step toward innovation, efficiency, and excellence in productio