Table of Contents

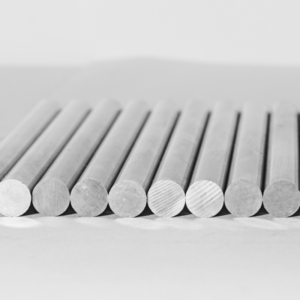

ToggleSolid Carbide Rods

In the contemporary world of machining, precision is not just a goal; it’s a necessity. Among the various tools that enable this level of accuracy, the **Solid Carbide Rod** stands out prominently. These rods have transformed the landscape of manufacturing, offering unmatched performance and efficiency. This article explores how solid carbide rods enhance machining processes, benefiting industries and operators alike.

Understanding Solid Carbide Rods

Solid carbide rods are made from tungsten carbide, a compound made from tungsten and carbon. This material is known for its hardness and wear resistance. Typically, solid carbide rods are used in the production of cutting tools, including drill bits, end mills, and insert tools. What makes these rods especially effective in machining is their ability to withstand high temperatures and pressure, maintaining their shape and effectiveness during operation.

The manufacture of solid carbide rods is a meticulous process. Precision grinding and sintering techniques yield rods that are uniformly dense and possess excellent structural integrity. The result is a tool that not only lasts longer than its counterparts but also delivers precise results, thereby mitigating downtime and increasing productivity in machining operations.

Advantages of Solid Carbide Rods

Enhanced Durability

One significant advantage of using solid carbide rods is their exceptional durability. For instance, when engineers use these rods in tool production, they create cutting tools that exhibit less wear over time. Consider a manufacturing facility where conventional steel tools are replaced with solid carbide tools; the output can increase dramatically, as tool replacement intervals extend. Manufacturers report extending tool life by 5 to 10 times, translating to fewer interruptions and lower costs in the long run.

Superior Cutting Performance

The cutting performance achieved with solid carbide rods is another crucial factor. These rods can maintain sharp edges longer, allowing for cleaner cuts and finer finishes. For example, industry professionals often cite their experience with precision machining of complex components, such as aerospace or automotive parts. The solid carbide rod-equipped tools can perform intricate cuts while minimizing the risk of material deformation, leading to higher quality products that meet stringent industry standards.

Resistance to High Temperatures

Machining processes often generate significant heat, potentially affecting the tool’s performance. Solid carbide rods excel in these situations due to their high heat resistance. This property is particularly advantageous in high-speed operations where traditional tools might struggle. Imagine a scenario in a machining center, running at high RPMs on tough metals like titanium; the solid carbide tool can withstand this without losing its hardness or edge. As a result, manufacturers can push the boundaries of what’s possible in terms of speed and efficiency.

Versatile Applications

Solid carbide rods are not limited to one particular application; their versatility is another reason behind their growing popularity in various industries. Whether in aerospace, medical devices, tool manufacturing, or any precision engineering, these rods provide tailored solutions. For instance, in the medical field, where precision machining is a must for implants, solid carbide tools can create parts with remarkable accuracy, which is critical in ensuring patient safety and equipment reliability.

In the automotive sector, solid carbide rods are used to produce components that require exact specifications. The automotive industry, striving for innovation and efficiency, benefits from the ability to create lighter yet stronger parts. Using solid carbide tools ensures that these parts can be produced quickly and with the needed precision to meet market demands.

Choosing the Right Solid Carbide Rod

When it comes to selecting the right solid carbide rod, there are several factors to consider. Buyers should look for rods that are appropriate for their specific machining needs. The diameter, length, and grade of the carbide rod play crucial roles in determining its effectiveness in particular applications. For instance, a thicker rod might be better for heavy-duty cutting, while a thinner rod could excel in precision work.

Additionally, the surface finish of the rod can influence performance. A well-finished solid carbide rod can lead to more effective machining outcomes by reducing friction and heat build-up during cutting operations. This not only prolongs the tool’s life but also enhances accuracy, proving beneficial in producing complex parts that demand exacting standards.

Cost Efficiency

Investing in solid carbide rods may also lead to long-term cost savings. Although they can be more expensive initially compared to traditional materials, the benefits often outweigh the costs. With extended tool life, reduced downtime, and superior performance, companies find that they save on replacement tools and improve the overall profitability of their operations. Businesses looking to remain competitive must look toward solutions like solid carbide rods that offer both performance and cost efficiency.

Conclusion

Solid carbide rods represent a leap forward in precision machining, offering numerous benefits that affect operational efficiency and product quality. Their durability, cutting performance, heat resistance, and versatility make them an essential tool in various industries. As manufacturing continues to evolve, the demand for effective and efficient solutions will grow, and solid carbide rods are poised to meet that demand.

Investing in the right solid carbide rod not only enhances the quality of the machined parts but also answers a fundamental question facing manufacturers today: how to maintain competitiveness in a rapidly changing market. By embracing the capabilities of solid carbide rods, businesses can enhance their efficiency and ensure they remain at the forefront of their respective industries. Ultimately, the investment in solid carbide rods is an investment in precision, quality, and future success.