Table of Contents

ToggleHigh Hardness Solid Carbide Rods

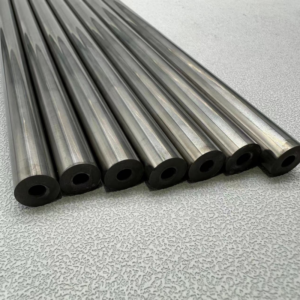

In the ever-evolving landscape of manufacturing, the quest for precision and durability is a common goal among machinists and engineers. One solution that has gained significant traction in recent years is the use of high hardness solid carbide rods. These rods are not just a tool; they represent an advancement in precision machining that enhances tool life and operational efficiency. This article explores the many benefits of high hardness solid carbide rods, their applications, and why they are becoming a staple in various industries.

Understanding High Hardness Solid Carbide Rods

At its core, a high hardness solid carbide rod is made from tungsten carbide, a compound of tungsten and carbon. This material is known for its exceptional hardness and wear resistance, making it a prime choice for cutting tools. When compared to other materials, such as high-speed steel or aluminum, solid carbide rods offer superior performance in terms of durability and precision. Data shows that these rods can outperform other materials by lasting up to ten times longer, depending on the application.

Benefits of High Hardness Solid Carbide Rods

1. Superior Durability

One of the foremost advantages of high hardness solid carbide rods is their robustness. In precision machining, durability matters. For instance, when machining hard materials like titanium or stainless steel, standard cutting tools often wear out quickly, resulting in frequent replacements and increased downtime. In contrast, carbide rods maintain their edge and structural integrity much longer. This enhanced durability not only reduces costs associated with tool replacement but also minimizes production delays.

2. Enhanced Precision

Precision is key in manufacturing, and high hardness solid carbide rods contribute significantly to achieving it. Their rigid structure allows for tighter tolerances and a more precise fit in machining processes. For example, in the aerospace industry, where components must meet exact specifications, the use of carbide rods ensures that parts are manufactured with impeccable accuracy. This level of precision directly affects the performance and safety of the final product.

3. Versatile Applications

High hardness solid carbide rods are not restricted to one industry; rather, their versatility makes them suitable for numerous applications. In the automotive sector, for example, these rods are used to create high-performance tools that cut through tough metals. As another example, they find use in the electronics industry where micro-machining is crucial. In this case, the fine-tipped tools fashioned from carbide rods create intricate designs on circuit boards, promoting further advancements in technology.

Customer Considerations

When selecting high hardness solid carbide rods, customers often weigh a variety of factors. Here are some key considerations:

A. Performance

For many customers, performance is paramount. This includes not just the obvious factors like cutting speed and durability, but also how the rods perform under stress. High hardness solid carbide rods exhibit low thermal expansion, meaning they retain their shape and sharpness even under high temperatures. This is particularly important in high-speed machining applications where heat can degrade tool performance.

B. Cost Efficiency

Cost is always a focal point in purchasing decisions. While high hardness solid carbide rods may come with a higher initial investment compared to other materials, their longevity and performance characteristics often lead to lower overall costs. For example, a machine shop investing in carbide rods may experience fewer tool changes and less downtime, leading to increased productivity and profitability over time.

C. Compatibility

Compatibility with existing machinery is another essential factor. High hardness solid carbide rods can be used with various cutting tools and machines. This adaptability allows customers to upgrade their current setups without the need for entirely new equipment, making the transition to carbide more seamless.

Real-World Examples

Consider a company in the aerospace sector that manufactures components for jet engines. They had been struggling with tool wear and inconsistent product quality using high-speed steel tools. After switching to high hardness solid carbide rods, they noticed a significant improvement. The tools lasted longer, allowing the machining process to run smoothly with fewer interruptions. Not only did they see cost savings from reduced tool replacements, but the quality of their components also improved, leading to higher customer satisfaction.

In another instance, an electronics manufacturer faced challenges when working with hard materials for their products. Traditional machining methods produced imprecise results, affecting the functionality of their electronic circuits. By adopting high hardness solid carbide rods for micro-machining, they were able to cut channels and features with unmatched precision, thereby enhancing the performance of their final products.

Conclusion: The Future with High Hardness Solid Carbide Rods

The benefits of high hardness solid carbide rods extend beyond mere tool performance; they represent a fundamental shift in how precision machining is approached. By embracing these durable and versatile tools, manufacturers can achieve unparalleled accuracy and efficiency. As industries continue to evolve, the demand for high performance in both precision and cost-effectiveness will only grow.

Ultimately, investing in high hardness solid carbide rods is not merely a purchase—it’s a strategic move towards enhancing productivity and maintaining a competitive edge in the market. By understanding the advantages and applications of these rods, companies can make informed decisions that will positively impact their operations for years to come. The future of manufacturing is here, and it’s built on the strength of high hardness solid carbide rods.